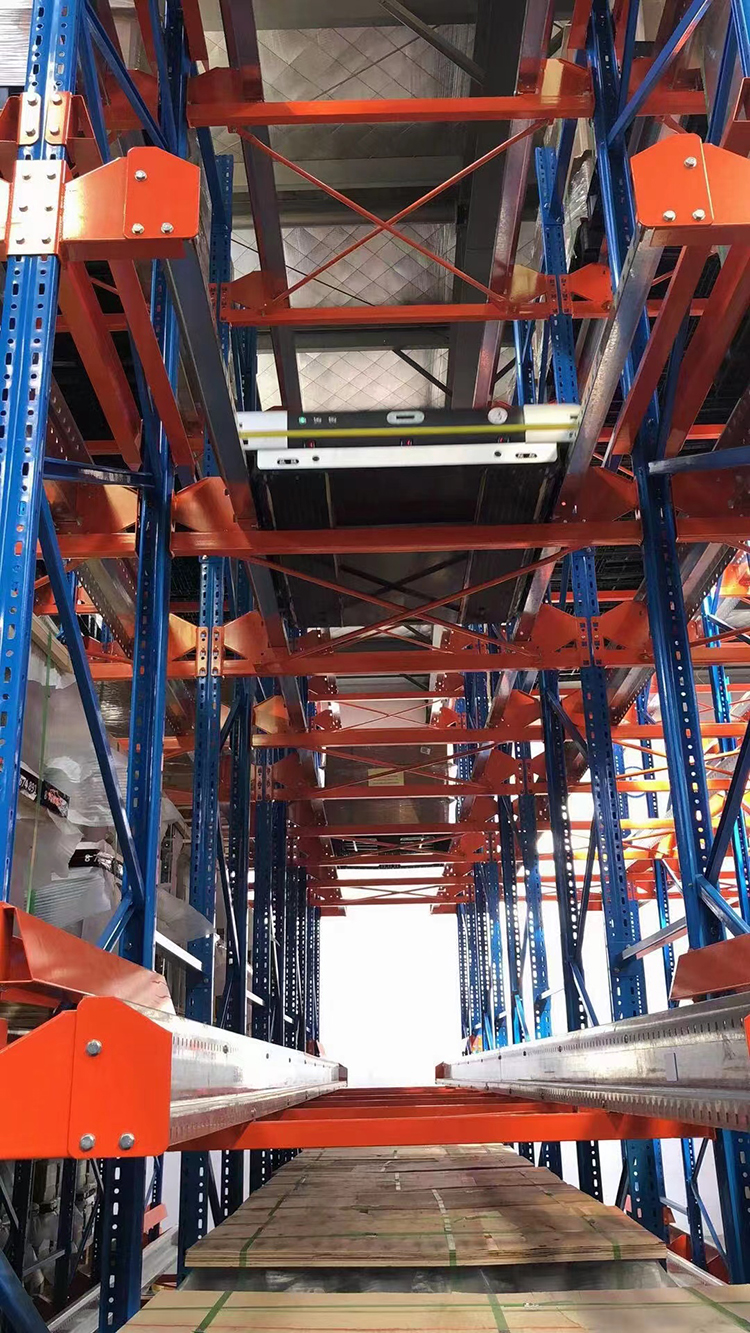

Last month, our company completed a shuttle racking project for a Malaysian customer. Under the detailed installation instructions and videos, our customer finished installation, and used successfully.They were very happy for our products.

Nowadays, shuttle racking system are widely used in warehouse storage.It greatly improves the utilization rate of the warehouse, and the whole space just need to keep small aisle for forklifts to load and turn around. More important,it is easy for using and operating.

Compared with heavy duty pallet racking, its warehouse utilization rate is higher. And in the same warehouse,it can store more pallets, because this racking system does not need to use aisles in each row, of course, correspondingly, the cost will be higher.

And compared with drive in racking system, there are many advantages:

1. It can realize first in first out and first in last out storage method, but traditional drive in racking just only can reach first in last out storage method.

2. In the depth direction, the channel can be set very long, even can reach 100pcs pallet space while drive in rack usually only can reach 13-15pcs pallet spaces.

3. It is easier to loading and unloading. We can use the remote control to control the shuttle car put the pallets to corresponding position. But for the drive in racking system, will be much more trouble,need to drive the forklift into the small aisle to take or put the pallets.In this situation, high quality special forklifts and high level driving skill operators will be needed.After all, the aisle is particularly narrow.

Of course, it also has its shortcomings, that is, the cost of the whole project will be higher than the drive in racking system. Of course, customers can choose the corresponding plan according to their actual storage needs. Our racking can be customized for clients.

Whatever big or small warehouse, we will design the solution for customer carefully, any interest, please email us at contact@lyracks.com

Post time: Apr-08-2022