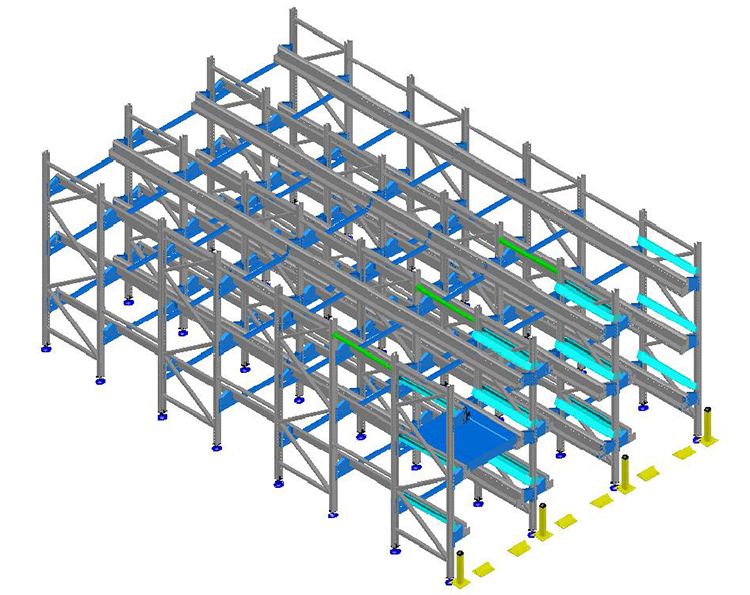

Shuttle Rack

Where to Buy Steel Pallet?

Of course From Liyuan factory.Shuttle racking is a high-density storage system which uses radio shuttle car to store and retrive pallets. The storage system mainly consists of frames, rail support beams, rail support plates, rails, guide plates, top bracers, ground stoppers, protectors, connect bars and several shuttle cars. This high efficient storage solution provides clients a new option to maximize use of warehouse.

Operation Principle

Loading: After getting orders from radio controller, shuttle car transports pallet from start of rail to deeper position of racking system, and then returns to start point.

Picking: Shuttle car moves pallets from the inner to the front of the racking, and then forklift picks up the pallets out of racking system.

Transferring: Shuttle car can be placed in different aisles by forklift, and one shuttle can be used in many aisles. Quantity of shuttle cars is often decided by aisle length, total amount of pallets, and efficiency of store and retrieve.

Specification

| Loading capacity | Length | Width | Height | |||

| 500-1500kg per pallet | 800-1400mm | 3-100 pallets | 2550-11,000mm | |||

| Special storage requirements are also available | ||||||

| Main Component | Racking+shuttle car | |||||

| Speed | Empty shuttle car - 1m/s; Loading the pallets - 0.6m/s | |||||

| Working temperature | From -30℃ to 40℃ | |||||

| Features | First In Last Out and First In First Out | |||||

Advantage

1. This racking system allows clients to maximize warehouse space by minimizing area of aisles required for trucks and forklift;

2. It can count quantity of stored pallets;

3. Space utilization rate is higher than pallet racking system and drive in racking system

4. Forklift does not need to enter aisle, safety can be guranteed when handling pallets

Why to choose us

1. We have experienced technologists;

2. Solution designing are FREE;

3. High Quality products with competitive price.

Project Case